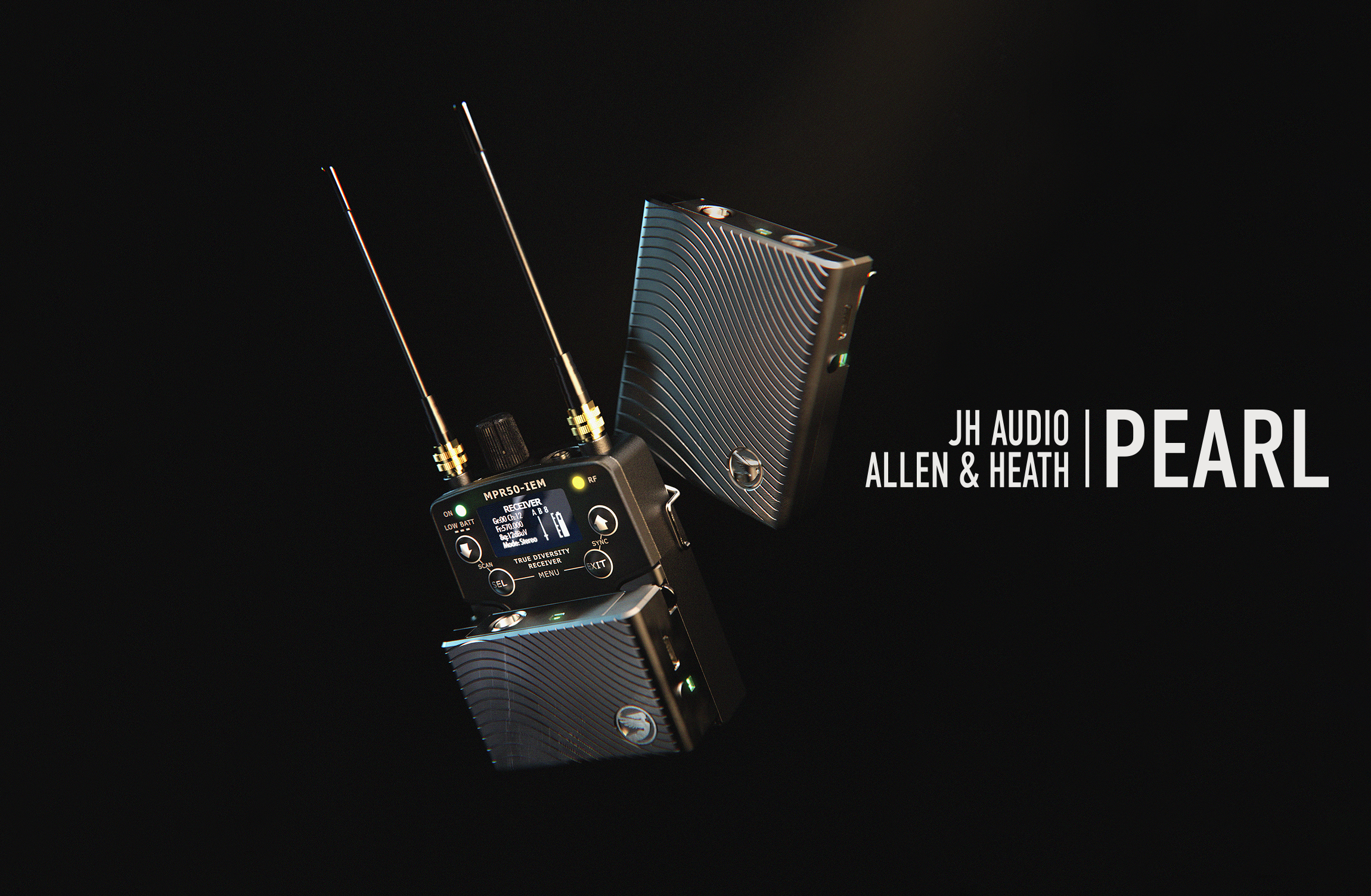

Modeled in Fusion 360 / Rendered in KeyShot

Led all phases of design including CAD modeling, form refinement, housing ergonomics, and CMF to create a durable, and future facing solution that merges audio fidelity with field tested functionality.

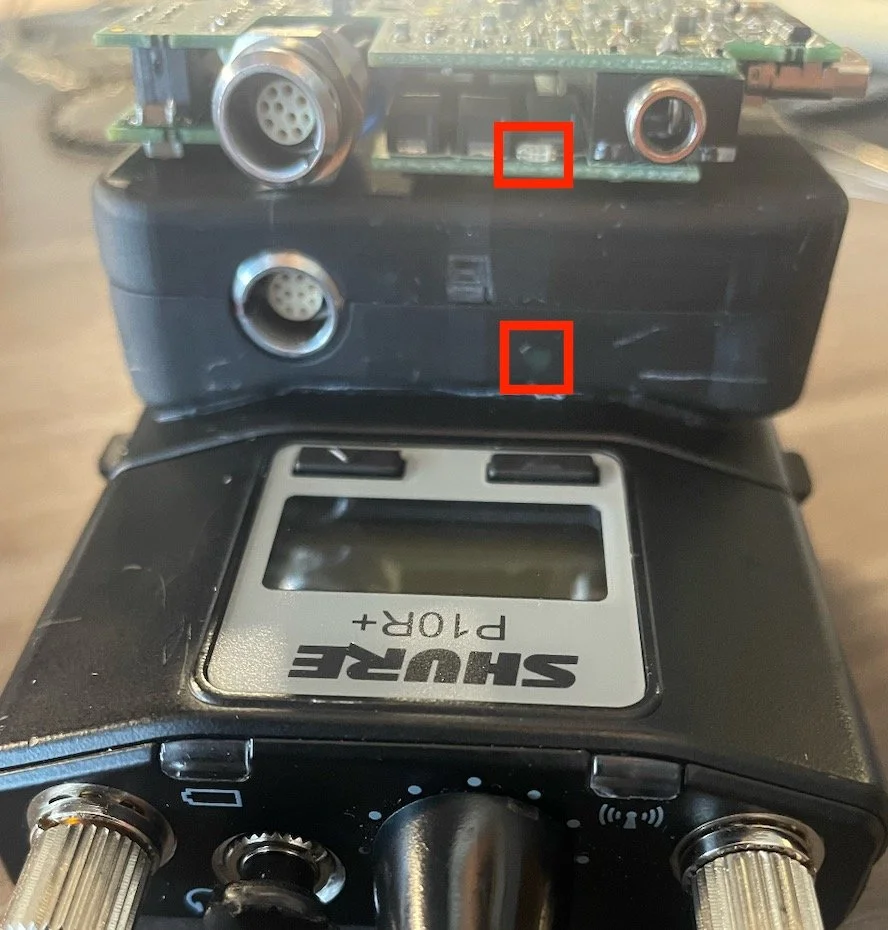

Collaborated with external mechanical, audio, and electrical engineering teams to develop the custom PCB boards and connectors.

Collaborated with Allen & Heath to develop the Pearl companion app and digital experience.

Led EVT, DVT, and PVT phases through full DFM analysis including software integration, engineering lab testing, ID lock, real world user testing, and prototype validation.

Managed design and development of packaging with internal teams and vendor partner.