Design Innovation | Experience Design | Cross-Functional Collaboration | Problem Solving

I designed a Digital Signal Processing (DSP) unit for JH Audio in collaboration with Allen & Heath, enabling users to store and apply multiple acoustic sound signatures directly to their headphones. By integrating custom EQ software and a USB-C interface, this device allowed for real-time flashing of custom sound profiles, making it possible to achieve professional-grade audio quality regardless of the speaker components used. This innovation reduced the need for larger, high-end components, allowing for a more compact, consumer-friendly form factor without sacrificing sound fidelity.

Reviewing overall depth I determined we would need to shave height and brainstorm ways to link the two units.

During the refinement phase we experimented with different case locations, shapes, and volumes, which meant the internal stackup was constanty changing.

EVT stage prototype used for lab and in-house validation of hardware and version one of the Pearl GUI.

Once we entered the DVT phase we began user testing with a handful of bands to in order to validate the hardware. This was Pearls first road trip with Mötley Crüe.

Once the hardware was validated we moved on to PVT prototypes. This is the first machined aluminum Pearl unit we recieved from our vendor, anodized matte black with a belt clip installed for stage use.

Shown here is one of the first production Pearl units, sold as a bundle with its own universal earpiece and Pelican case packaging.

The finished Pearl DSP unit on stage for the first time, linked directly to a Wisycom wireless transmitter pack.

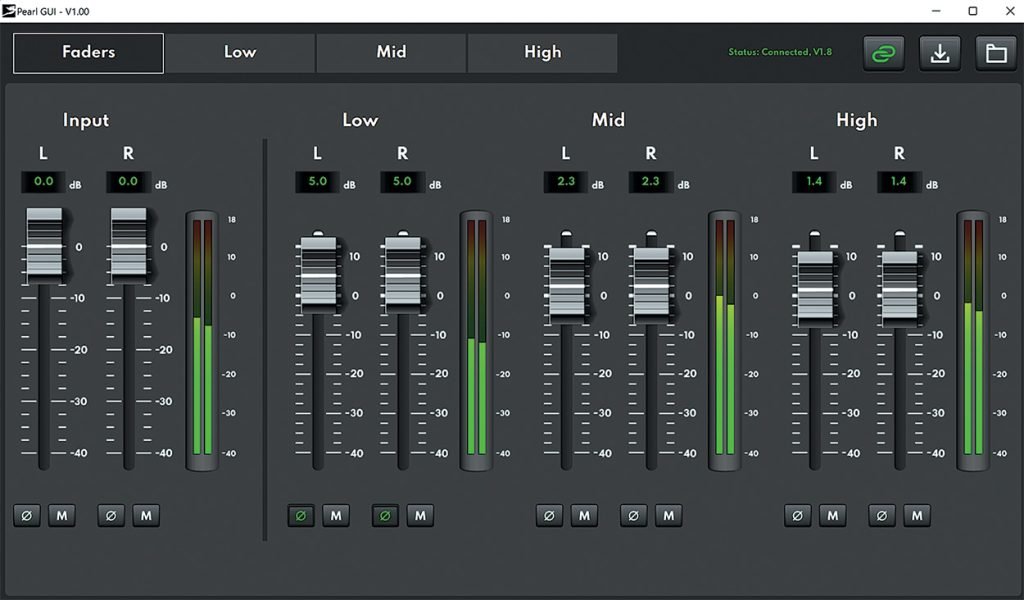

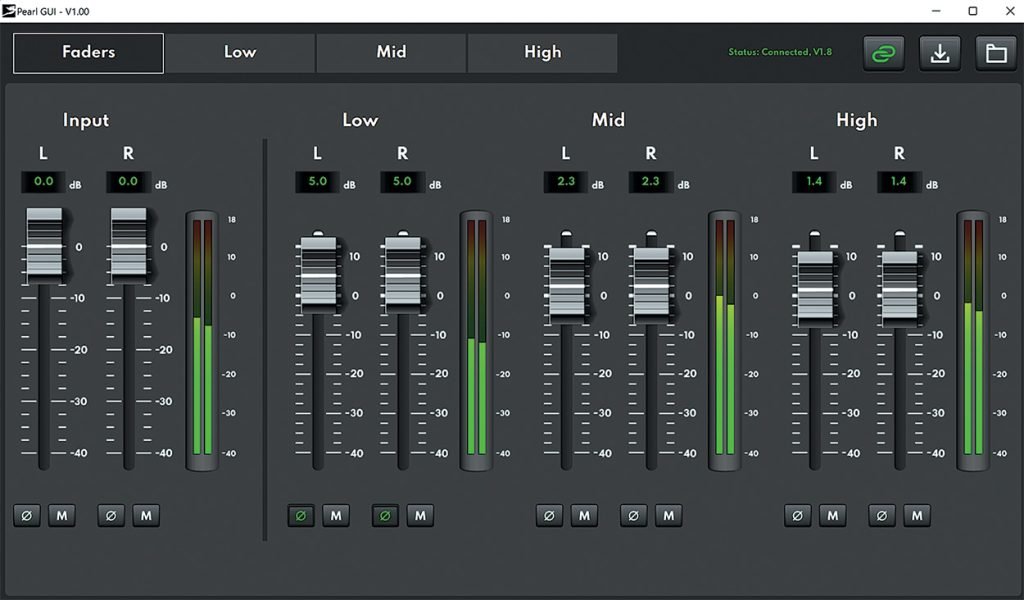

I also had a hand in designing and developing the Pearl UX/UI/GUI. These are some early screenshots from the EVT phase.

More app development showing the ability to modify and shape indiviual sound curves to the users liking. These would then be flashed straight to the device altering the sound of the earpiece.